Leave Your Message

In the realm of industrial safety and efficiency, Paint Booth Filters play a critical role. Experts like David Reed, a veteran in the coatings industry, have emphasized, "Quality filters are vital to a safe working environment." His words highlight the importance of investing in top-notch filters.

Effective Paint Booth Filters enhance performance and ensure safety. Choosing the right filter can significantly impact air quality. It can also reduce pollutants in the workspace. Many companies may overlook the nuances of filter selection. This oversight can lead to operational inefficiencies and potential safety hazards.

The market in 2026 is expected to offer advanced options for Paint Booth Filters. Various materials and technologies are being developed. However, it's essential to remain cautious. Not all filters will guarantee improved performance. Ensuring compliance with standards is crucial. Reflection on previous filter choices can guide better decisions. As you make selections, consider both safety and efficiency.

Paint booth filters play a crucial role in ensuring a safe and efficient environment for spray painting operations. According to a report by the Environmental Protection Agency, around 7% of workplace-related injuries stem from improper ventilation and air quality. The right filters not only protect workers from harmful airborne particles but also improve paint application quality. When filters become clogged or contaminated, the risk of overspray increases, leading to more waste and potential safety hazards.

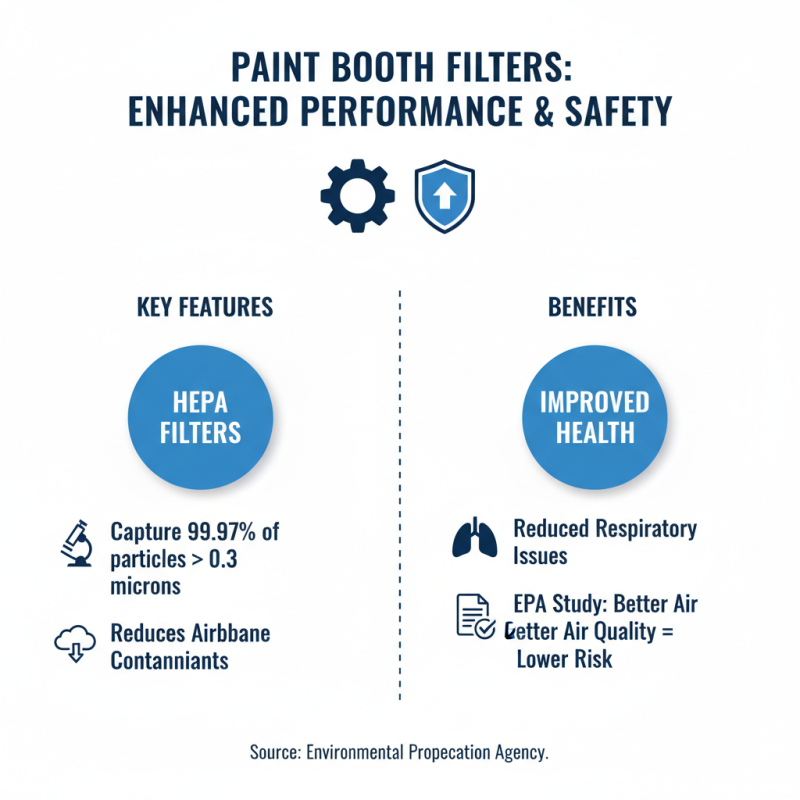

Regularly monitored and replaced filters can significantly enhance booth performance. For instance, studies show that using high-efficiency particulate air (HEPA) filters can capture up to 99.97% of particles, including those as small as 0.3 microns. This capability minimizes toxic exposure. However, it is important to remember that not all filters are created equal. Some might fail to meet the necessary standards, leading to inefficiencies. Continual reassessment of filter efficiency is essential for maintaining a healthy work environment.

In many cases, operators overlook the importance of filter maintenance. Neglecting this aspect can lead to increased operational costs and downtime. The industry average suggests that inadequate filter management can inflate operational expenses by up to 30%. Workers must be educated about the signs of filter degradation. Awareness can lead to timely replacements and a safer workspace for everyone involved.

| Filter Type | Filtration Efficiency (%) | Particle Sizes Captured (microns) | Lifespan (Months) | Material Type |

|---|---|---|---|---|

| HEPA Filter | 99.97 | 0.3 | 12 | Fiberglass |

| Activated Carbon Filter | 95 | 0.5 | 6 | Activated Carbon |

| Paint Arrestor Filter | 85 | 1.0 | 3 | Synthetic Fiber |

| Pre-Filter | 75 | 5.0 | 9 | Polyester |

| High-Efficiency Filter | 99 | 0.5 | 10 | Microfiber |

When it comes to paint booths, filters are crucial. They enhance performance and safety. Different types of filters serve various functions. Understanding these types is essential for optimal results.

High-efficiency particulate air (HEPA) filters are popular. They capture 99.97% of particles of 0.3 microns. This level of filtration is necessary in automotive and industrial paint applications. Additionally, activated carbon filters help control odors. They absorb harmful volatile organic compounds (VOCs). VOCs may cause health issues. Reports indicate VOC levels can exceed 600 ppm in poorly ventilated spaces. A reliable filter can significantly reduce this risk.

However, it’s essential to monitor and maintain these filters. Over time, filters become clogged and less effective. A common oversight is neglecting to replace filters regularly. This can lead to decreased air quality and even accidents. Regular inspection protocols can improve safety. Industry data shows that up to 30% of workplace accidents in paint booths result from poor air quality. Implementing strict maintenance routines will contribute to better health and safety standards.

When selecting paint booth filters, key features can enhance both performance and safety. High-efficiency particulate air (HEPA) filters are a top choice. They capture 99.97% of particles larger than 0.3 microns. This level of filtration is crucial in reducing airborne contaminants. A study by the Environmental Protection Agency highlighted the increased risk of respiratory issues in environments with poor air quality.

Another important feature is the filter's durability. Many filters can withstand high-velocity airflow, lasting longer than standard options. A report from the National Institute for Occupational Safety and Health states that well-maintained filters can enhance air quality and reduce maintenance costs by up to 30%. It's vital to choose filters that are easy to replace. Frequent replacements can lead to increased downtime and costs.

Consideration of the filter's pressure drop is essential. A lower pressure drop means better airflow and reduced energy consumption. However, achieving the perfect balance between filtration and airflow is a challenge. Not all filters meet this criterion equally. Often, performance compromises arise when budget constraints limit options. Finding filters that do not sacrifice safety for cost is a critical reflection point.

When choosing paint booth filters, safety must be a priority. Poor filtration can lead to hazardous conditions. Ensure filters capture harmful particles effectively. Some filters may not meet safety standards. This oversight can expose workers to toxic fumes and particles.

Consider the filter’s material. Certain materials better contain flammable vapors. Always assess the filter’s compatibility with the paints used. Mismatched filters can fail during operation. This could result in a dangerous buildup.

Regular maintenance is crucial. Filters should be checked routinely and replaced as needed. Over time, clogged filters can reduce airflow. This raises fire risks and hinders performance. Addressing these issues can feel overwhelming. However, prioritizing safety leads to a more efficient workspace. Balancing performance and safety in filter selection is essential.

This chart compares the airflow resistance and particulate removal efficiency of the top five paint booth filters in 2026. Maintaining balance between airflow resistance and efficiency is crucial for enhanced performance and safety in paint booth operations.

In 2026, choosing the right paint booth filters is crucial for operational efficiency and worker safety. Recent industry reports indicate that up to 80% of air quality issues in paint booths stem from inadequate filtration systems. Many businesses overlook this. High-quality filters capture harmful particles, reducing contamination risks. This is essential for compliance with safety standards.

The top models for 2026 offer advanced filtration technology. For instance, HEPA filters can trap at least 99.97% of particles down to 0.3 microns. Some filters incorporate activated carbon to neutralize odors. However, installations require precise fitting. Poorly fitted filters can lead to leaks, negating their benefits.

The market is filled with varied options, but not all are equal. Certain filters promise high efficiency but may underperform. Regular maintenance is often ignored, too. Dust and paint buildup can cause filter failure, impacting air quality. Choosing the right model entails more than brand recognition; it demands consideration of specific booth requirements and ongoing upkeep. An informed decision can significantly enhance performance and safety.